In order to meet the high-precision and high-efficiency requirements of the water-cooling plate pressing of the battery pack of new energy vehicles, we have launched a frame guide hydraulic press. This equipment is designed for the new energy vehicle industry.

In the precision manufacturing field, 0.001 mm (1 micron) mean is equivalent to an error control of 1/70 of a hair, which is a limit that many high-end hydraulic press machines cannot reach. While some China hydraulic press supplier can achieve this accuracy.

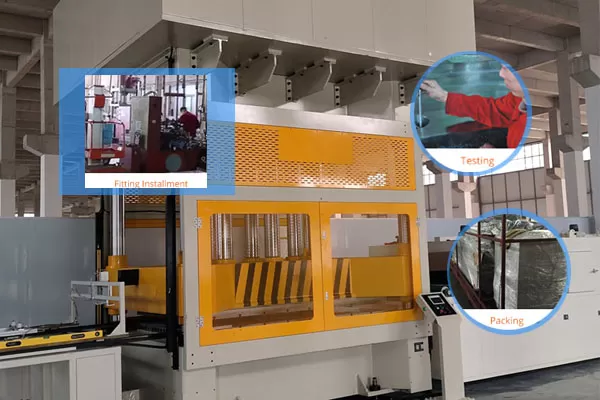

Goodsjack has worked hard on refined management and specially hired a professional refined management consulting agency to provide on-site guidance, resolutely achieving lean production, and unqualified products will not leave the factory. The pre-delivery process for hydraulic press manufacturing involves a series of quality checks and preparations, including testing, final inspections, and ensuring all components are correctly installed and functioning, before the press is shipped to the customer.

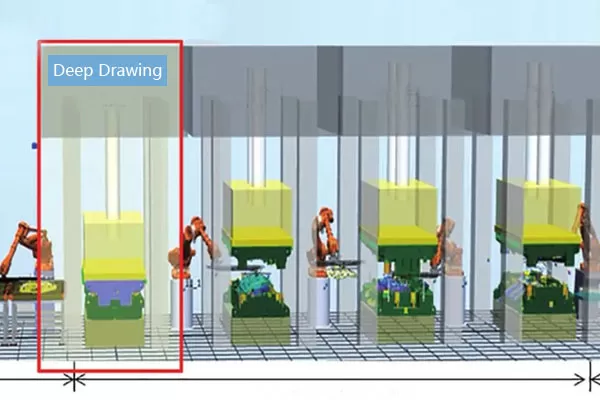

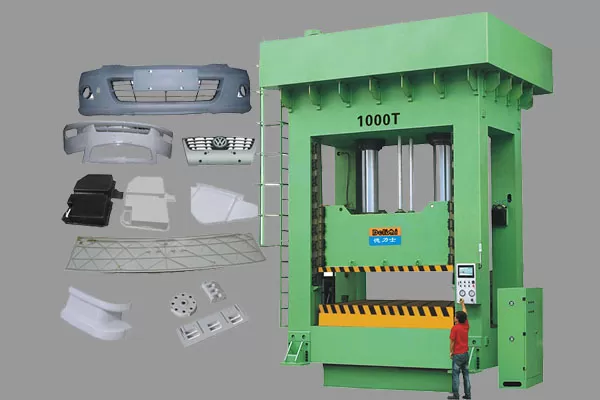

A deep drawing hydraulic press production line is an integrated system designed for manufacturing complex metal parts through the deep drawing process, which involves forming sheet metal into three-dimensional shapes using hydraulic pressure. Goodsjack's deep drawing hydraulic press production line solution aims to build an advanced and reliable deep drawing hydraulic press production line for enterprises, helping them to improve production efficiency, reduce costs and improve product quality.

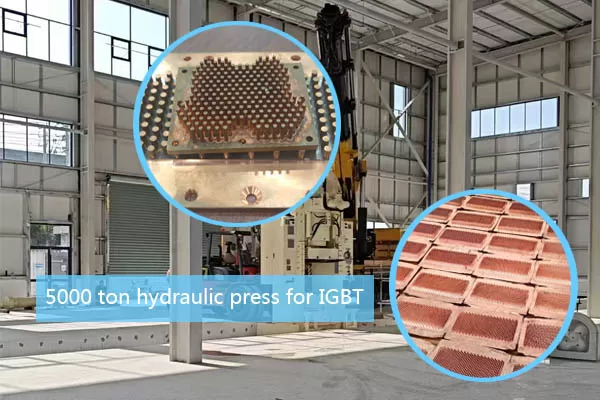

With the continuous improvement of IGBT module power density in the fields of new energy vehicles and rail transportation, the heat sink, as the "temperature steward" of the power electronic system, is undergoing a revolutionary upgrade in its processing technology. With its unique advantages, hydroforming technology of Delishi/Goodsjack is bringing about a dual transformation in efficiency and precision in the field of IGBT heat sink manufacturing.

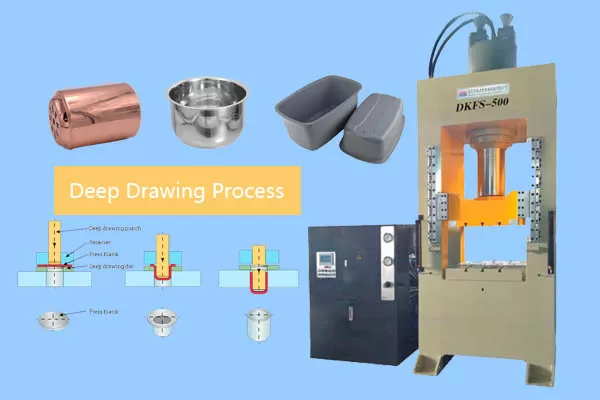

A deep drawing hydraulic press is a versatile machine used to form metal sheets into complex shapes by drawing them into a die. The process is commonly used in industries like automotive, aerospace, and appliance manufacturing. The choice of material is critical for successful deep drawing, as different materials have varying levels of ductility, strength, and formability.

Deep drawing hydraulic presses are popular for several reasons, primarily due to their versatility, precision, and efficiency in manufacturing processes.

Deep drawing is a manufacturing process used to transform sheet metal into complex, hollow shapes. It is widely used in industries such as automotive, aerospace, and consumer goods. Goodsjack offers high quality deep drawing presses with a wide range of output capacity and table sizes that can be completely customized.

A hydraulic press machine ensures precision in its operations through a combination of advanced design features, control systems, and hydraulic mechanisms.

Setting up a deep drawing hydraulic press for success involves careful planning, proper equipment selection, and adherence to best practices. Deep drawing is a manufacturing process used to form sheet metal into complex shapes, and a hydraulic press is often the preferred machine for this task due to its ability to provide consistent force and control.

The future outlook of the hydraulic press industry can be analyzed from multiple perspectives such as technological development, market demand, and environmental protection trends.

Cold forging hydraulic press is a widely used equipment in metal processing and other fields. It has the following 7 benefits, high-precision forming, high material utilization rate, improve product strength, good surface quality, high production efficiency, long mold life and energy saving and environmental protection.

On January 12, 2025, under the bright sunshine, Guangdong Delishi Technology Co., Ltd. welcomed the highly - anticipated groundbreaking ceremony for its new factory. The site was bustling with activity as employees, partners, and local dignitaries gathered together to witness this significant moment. The air was filled with vibrant energy and anticipation for the future.

Following are the main methods about how to adjustable the speed of hydraulic press. Adjusting the flow of hydraulic pump, adjusting the structural parameters of the hydraulic cylinder and control the valve opening in the hydraulic circuit.

As another year draws to a close and the holiday season is upon us, GoodsJack/Delishi would like to express our sincere gratitude to all our employees for their hard work and dedication throughout the year. We would also like to thank our valued customers for their continued support and trust.