1. Understand the Requirements

● Material Properties: Know the type of metal being used (e.g., aluminum, steel, stainless steel) and its thickness, ductility, and tensile strength.

● Part Design: Analyze the geometry of the part, including depth, diameter, and corner radii, to determine the required force and tooling.

● Production Volume: Decide whether the setup is for prototyping, low-volume, or high-volume production.

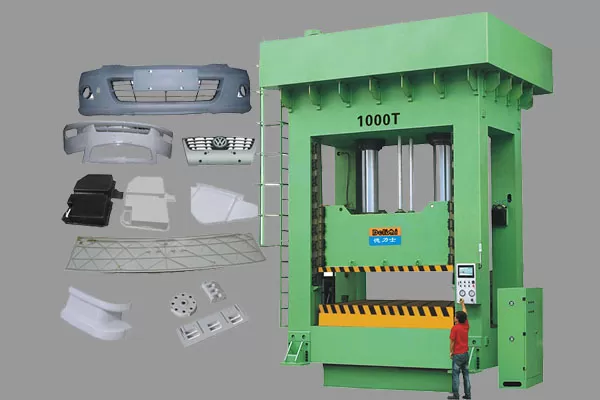

2. Select the Right Hydraulic Press

● Tonnage: Choose a press with sufficient tonnage to handle the deep drawing process. The required force depends on the material, part size, and depth of draw.

● Stroke Length: Ensure the press has enough stroke length to accommodate the depth of the part.

● Bed Size: The press bed should be large enough to hold the tooling and workpiece.

● Control System: Opt for a press with precise control over speed, force, and dwell time to ensure consistent results.

3. Design and Fabricate Tooling

● Die and Punch: Design the die and punch to match the part geometry. Use high-quality tool steel or carbide for durability.

● Clearance: Ensure proper clearance between the punch and die to account for material thickness and prevent cracking or wrinkling.

● Surface Finish: Polish the tooling surfaces to reduce friction and improve part quality.

● Blank Holder: Use a blank holder to control material flow and prevent wrinkling during the drawing process.

4. Prepare the Material

● Blank Size: Cut the metal sheet to the correct blank size, accounting for material stretch and shrinkage.

● Lubrication: Apply a suitable lubricant to reduce friction between the tooling and the material, improving formability and extending tool life.

● Material Annealing: For deep or complex draws, consider annealing the material to soften it and improve ductility.

5. Set Up the Press

● Install Tooling: Securely mount the die, punch, and blank holder in the press, ensuring proper alignment.

● Adjust Parameters: Set the hydraulic press parameters, including:

● Force: Adjust the tonnage based on the material and part requirements.

● Speed: Control the drawing speed to avoid tearing or wrinkling.

● Dwell Time: Set the dwell time at the bottom of the stroke to ensure proper forming.

● Test Run: Perform a test run with a sample blank to check for issues like wrinkling, tearing, or misalignment.

6. Monitor and Optimize

Inspect Parts: Regularly inspect parts for defects such as cracks, wrinkles, or uneven walls.

Adjust Parameters: Fine-tune the press settings and tooling as needed to improve part quality.

Maintenance: Keep the press and tooling well-maintained to ensure consistent performance.

7. Safety Considerations

Guarding: Install safety guards to protect operators from moving parts.

Training: Ensure operators are trained in safe press operation and emergency procedures.

Regular Inspections: Check the press and tooling for wear or damage before each production run.

8. Troubleshooting Common Issues

Wrinkling: Increase blank holder force or adjust lubrication.

Tearing: Reduce drawing force, improve lubrication, or anneal the material.

Misalignment: Check and realign the tooling.

By following these steps, you can set up a deep drawing hydraulic press for optimal performance and high-quality results. Proper planning, tooling design, and process control are key to success in deep drawing operations.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail