Joseph Bramah invented the hydraulic press in 1795. Sometimes, it is called the Bramah press. Leading up to this invention, Bramah first invented the flush toilet, then began studying fluids. This lead to his study of Pascal’s law, also known as Pascal’s principle. This is a principle of fluid dynamics that states that when pressure changes anywhere in a confined space of fluid that cannot be compressed, that same pressure change will be transmitted throughout the whole space.

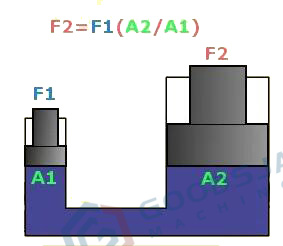

Experimenting with this principle, Bramah put together a device featuring two cylinders, one large and one small, filled with liquid and connected with a pipe. He realized that if he put pressure on the top of the narrow cylinder, this pressure would transfer to the liquid in the larger cylinder. He and a colleague then figured out to put together a device featuring cylinders with matching pistons sealed with leather and self-tightening collars. This was the basis for the hydraulic press, which works using liquid pressure as force.

The hydraulic press was a great innovation. Before its invention, the hydraulic engineering industry was virtually non-existent. During the 19th and 20th centuries, manufacturers and engineers used the hydraulic press to innovate in many areas, including most notably farming machinery and transportation. Today, hydraulic presses work using the same principle and basic components, but they are more varied than ever and frequently work in conjunction with CNC technology.

First, hydraulic fluid is forced into a small double-acting cylinder by a hydraulic pump or a lever. There, the fluid encounters a sliding piston, which tries to compress the fluid. It instead shoves the fluid through the small cylinder into a larger cylinder, where the process repeats. This time, the compressive force forces the fluid back into the smaller cylinder. The fluid is passed back and forth between cylinders, causing pressure to build. Eventually, the pressure becomes too great that it reaches the anvil, baseplate or die. It presses the anvil, baseplate or die, deforming the material beneath it into the desired product shape. To make sure that the press does not overload the material, when it reaches its pressure threshold, the fluid activates a valve that activates pressure reversal.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail