1) An in-depth analysis of the hydraulic system diagram, combined with the relevant electromagnet action table and related circuit diagrams, to figure out the complete working mechanism of the circuit. At the same time, correctly understand the circuit design intent and ideas, technical measures taken, and related background.

2) Correspond to the working principle diagram of the hydraulic press with the real object to form a specific impression. The pipeline in the hydraulic circuit, the schematic diagram is much different from the real object. If possible, make clear the relationship between the collusion between the valve holes on the valve plate and the barrier resistance. These factors are closely related to the circuit inspection.

2 Analysis of the non-maintaining pressure of the main cylinder

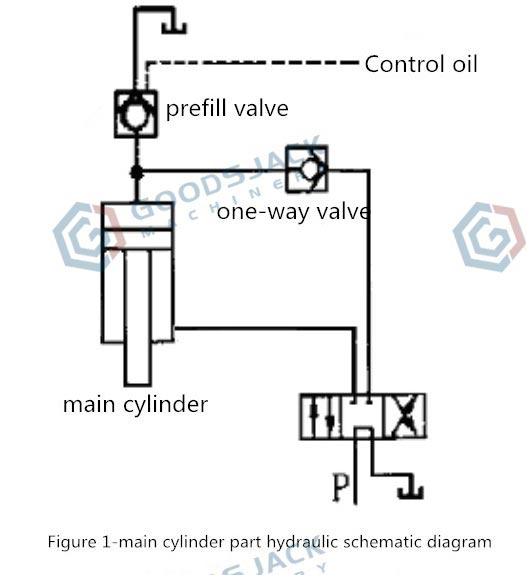

The main cylinder of the four-column hydraulic machine shown in the Figure uses a liquid filling valve to achieve rapid downward movement. The main cylinder often does not maintain pressure. The machine has pressure retention requirements,

and generally requires a pressure drop of <2 to 3 MPa within 10 minutes.Analysis: If the main cylinder does not maintain pressure, it must be a pressure oil leak. From the schematic analysis, it is related to the oil circuit,and there are no more than 5 components that cause leakage.

1) Pipes and joints: stress, poor welding, cracks, etc .;

2) Holding pressure one-way valve: poor sealing;

3) Prefill valve body: poor sealing or loose valve seat;

4) Prefill valve control oil push rod: slightly longer, lift and unload the small spool;

5) Main cylinder piston (guide bush): the seal ring is damaged.

Exclusion method: According to the analysis results, check and exclude from simple to complex, and from outside to inside.

Firstly, check the pipe and joints (from simple to complex, from outside to inside), and perform initial welding for poor welding and cracks.

It is best to remove the O-ring seal at the joint and heat the bend with red oxygen after heating. Lightly put the nut, wait for cooling setting then assembly.

If there are no defects in the pipelines and joints, check the pressure-holding check valve (from the outside to inside), remove the one-way

valve plug, polish its sealing line. Grinding it with the valve seat, clean it and assemble it.After checking the push rod valve,

if the main cylinder still cannot maintain the pressure, the prefilling valve should be checked. The main inspection is confirming whether

the seal line and the seat ring are loosening, then polish or reassemble the seat ring.

After the prefilling valve is checked, the pressure still cannot be maintained. It can be basically determined that the seal ring of the main

cylinder is damaged, and it can be removed and replaced.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail