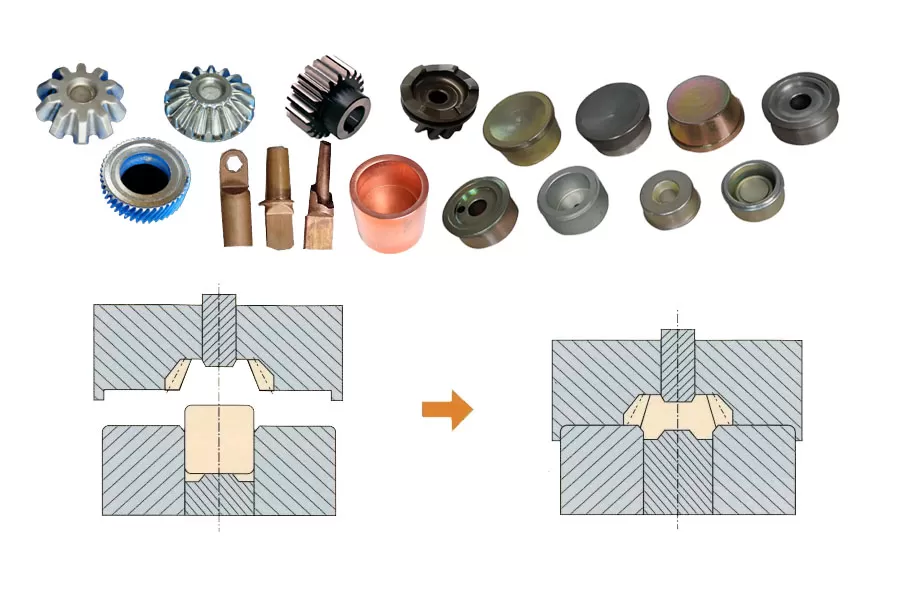

Cold forging press is one type hot selling hydraulic press machine of Goodsjack/Delishi Hydraulic Machinery. Cold forging is a metal shaping technique where metal bar stock is placed into a die and pressed into another closed die at ambient temperature or lower than the metal's austenite temperature. This process is highly efficient and cost-effective for producing large quantities of components.

Process Method of Cold Forging Press

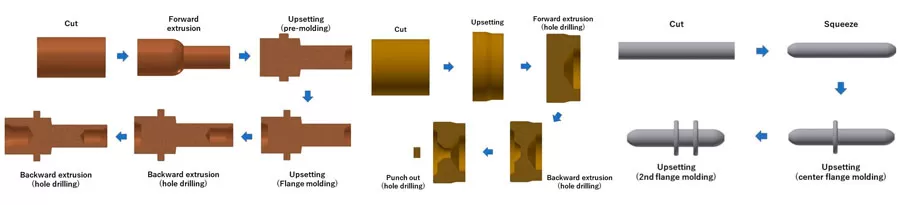

Upset processing

This is a forging and press-forming method that makes the material short and thick by tapping the material fixed with a die in the axial direction with a punch.

Used to machine the head of forged and pressed parts such as rivets and bolts.

Forward extrusion

By tapping the material with a punch on a small diameter die relative to the original material diameter, the diameter of the material is narrowed down and the amount of extra material squeezed and the length of the material is increased.

Backward extrusion

When the material is placed in a die and a force is applied with a small punch against the die material diameter, the material escapes into the gap between the die and the punch, resulting in a cup-shaped shape.

Used for forged parts machining and press-forged parts machining, such as caulked parts of rivets.

With cold forging press, in cold forging process, we manufacture forged and pressed parts by combining a "punch" that applies force directly to the material to apply plastic deformation and a "die" that receives the material to which the force is applied.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail