The hydraulic press machine is studied on the basis of absorbing Western advanced experience and technology. Today, with the increasingly developed technology power, the performance of the hydraulic press machine is gradually increasing.

Hydraulic press with two pieces in one mold is a kind of metal stamping and forming hydraulic press. It is equipped with various specifications of forming molds, which saves time and trouble for one-time forming.

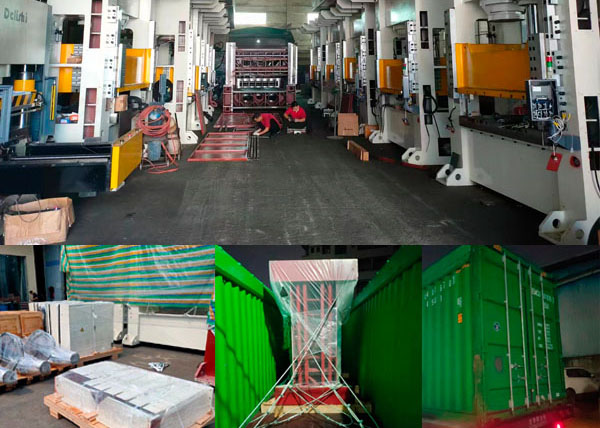

Thank you customers for their trust in our hydraulic press machines! After more than two months of hard work..

Good anti-wear, anti-rust and anti-corrosion properties can slow down hydraulic press machine wear and prolong service life.

SMC table-tennis table is a typical fitness equipment. At present, the mainstream production method is a one-time molding process of hydraulic press machine.

Oil leakage of hydraulic presses is mainly caused by insufficient pipeline quality, non-compliant pipeline installation, pipeline aging or pollution.

The Hydraulic Compression Molding Press for Graphite Saggar adopts a four-beam and four-column structure, and the pressing method is that the upper pressing mold frame floats, which produces the required relative motion to the lower mold to achieve the double-sided pressing effect.

Hydraulic press machine consists of two parts: the main engine and the control mechanism. The main engine part includes the fuselage, the main cylinder, the ejector cylinder and the liquid filling device. T

Hydraulic press machine for molded aramid ballistic helmet, recommended composite material hydraulic press, mainly used for the forming process of various composite materials, such as glass fiber reinforced plastic resin composite materials, SMC, BMC, Kevlar and other materials

At Delishi/Goodsjack, we not only provide high-quality deep drawing press machine, we also have the unique capability to draw a multitude of shapes in sizes far larger than most other manufacturers. And we can do it in a variety of materials, including stainless, cold rolled carbon, low alloy, and commercial and high-strength carbon steels, as well as aluminum, copper, brass, and more.

Our automatic ceramic power compacting press machines(also called ceramic power hydraulic presses) are manufactured in capacities from 50 tons to 5000 tons for single-level or multi-level parts for carbides, ceramics, powder metals, polymers and other particulate material industries.

Hydraulic presses play an important role in the automotive manufacturing industry. According to statistics, 60% to 80% of the parts on the car are produced by hydraulic press machine. Therefore, the hydraulic press machine has an important influence on the product quality, production efficiency and production cost of the automobile.

The structure of the car door sheet metal parts is complex, which affects the overall performance of the car door. According to the processing requirements of the car door, the car door sheet metal drawing hydraulic press can be selected. With the mold, the car door sheet metal can be integrally formed. This hydraulic press adopts frame structure, which can significantly improve product quality.

Today, when the manufacturing of hydraulic forging presses in the West is at a bottleneck, it took China only 8 years to break through the bottleneck and manufacture a heavy equipment weighing 80,000 tons.

The precision servo CNC hydraulic press drives the oil cylinder to perform the upper and lower pressing operations through the CNC hydraulic system. The man-machine interface operation window is connected, and the pressing parameters of the product can be set according to the customer's pressing product on the configuration touch screen, which can intuitively view the pressing of the product.