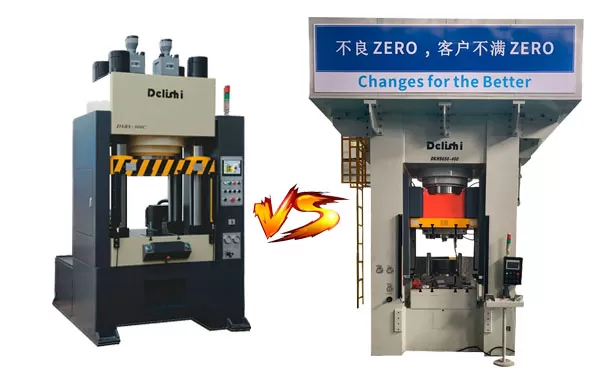

Structural features

Frame hydraulic press: It adopts an integral steel plate welded frame frame with good overall rigidity and high compressive strength; most of the sliders are guided by 45° inclined rails with high guiding accuracy; the fuselage structure is usually composed of an upper crossbeam, a lower crossbeam and two columns, which can form a larger upper and lower activity space for easy pressing of the workpiece.

Four column hydraulic press: It adopts a four-column three-plate structure with better rigidity and accuracy; it consists of a hydraulic cylinder, a crossbeam, a column and a filling device, and has a simple, economical and applicable structure.

Performance parameters

Frame hydraulic press: It starts pressing quickly after the mold is closed, and it takes only more than 1 second to reach the rated pressure; the pressure can be adjusted according to the pressing process requirements; it adopts a lower-mounted cylinder, which is convenient for replacing and cleaning the cylinder.

Four column hydraulic press: working pressure and stroke can be adjusted within the specified range according to process requirements; it adopts advanced master-slave hydraulic circuit, low oil temperature, empty stroke speed is above 10MM/second, and working speed is below 20MM/second.

Operation control

Frame hydraulic press: the equipment is usually equipped with advanced hydraulic system and electronic control device, which makes operation easier, can preset working pressure, and is equipped with electronic digital tonnage display; some frame hydraulic presses adopt independent movable pump station design, which is convenient for maintenance and operation.

Four-column hydraulic press: it has independent power mechanism and electrical system, adopts button centralized control, can realize three operation modes of adjustment, manual and semi-automatic, reliable action, long service life, small hydraulic shock, and reduces connecting pipelines and leakage points.

Application range

Frame hydraulic press: it is suitable for assembly, disassembly, straightening, calendering, stretching, bending, punching and other work of machine parts, truly realizing one machine for multiple uses; it is widely used in automobile, aviation, metal processing, plastic product processing and other industries, and is used for various processes such as pressing, correction and assembly.

Four column hydraulic press: suitable for the pressing process of plastic materials, such as powder product molding, plastic product molding, cold (hot) extrusion metal molding, thin plate stretching, as well as horizontal pressing, bending pressing, turning through, correction and other processes; commonly used in metal material drawing, bending, flanging, cold extrusion, punching and other processes, also suitable for correction, press fitting, powder products, abrasive products, pressing molding and plastic products, pressing molding of insulating materials.

Price Cost

Frame hydraulic press: Due to its relatively complex structure, high welding process requirements, and some high-end models are equipped with advanced hydraulic systems and electronic control devices, the price is generally relatively high.

Four column hydraulic press: The structure is simple, economical, practical, and the price is relatively affordable, especially some small four-column hydraulic presses, which have a high cost performance in the market.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail