Automotive parts manufacturing

Valve tappets in engines: Through the cold extrusion process, high-precision and high-strength valve tappets can be manufactured to improve the performance and reliability of the engine.

Gearbox gears: The cold extrusion process enables gears to have better tooth shape accuracy and surface quality, enhancing transmission efficiency and durability.

Electronic equipment manufacturing

Metal shells in mobile phones: Using the cold extrusion process, thin and strong metal shells can be created to improve the texture and protection performance of mobile phones.

Computer connectors: Connectors manufactured by cold extrusion have good conductivity and plug-in stability.

Hardware tool manufacturing

Wrenches: Cold extruded wrenches have higher strength and durability and can withstand greater torque.

Screws and nuts: Screws and nuts produced by cold extrusion have significantly improved quality and precision.

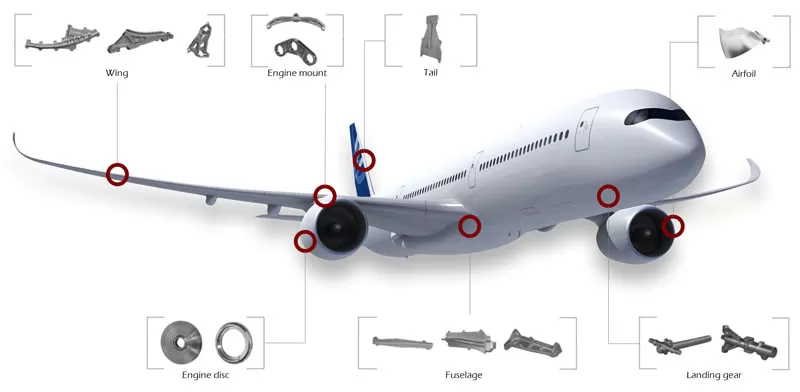

Aerospace field

Aircraft landing gear components: Cold extruded landing gear components have excellent strength and fatigue resistance to ensure flight safety.

Medical device manufacturing

Surgical instruments: For example, tweezers, pliers, etc., the cold extrusion process ensures the precise size and good corrosion resistance of the instruments.

Take a certain automobile manufacturing company as an example. They use cold extrusion process to produce engine connecting rods. Compared with traditional processes, the strength of cold extruded connecting rods is increased by 20%, the weight is reduced by 15%, and the production efficiency is greatly improved, reducing production costs.

In an cold forging press manufacturer, the mobile phone middle frame manufactured by cold extrusion process not only realizes complex appearance design, but also significantly improves the surface hardness and wear resistance, reduces the occurrence of scratches and wear, and improves product quality and user experience.

These cases fully demonstrate the successful application of cold extrusion process in different industries, and play an important role in improving product quality, reducing costs and enhancing competitiveness.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail