Top Hydraulic Forging Press Companies in Market. Hydraulic forging presses are used wherever high forces...

The accuracy of the four-column hydraulic press machine must be adjusted before the equipment is operated so that it...

Most hydraulic press machines use three-phase asynchronous motors to drive constant power variable pumps to provide...

Delishi/Goodsjack Hydraulic Press Machinery - Your Trustable Hydraulic Press Machine Manufacturer

With the development of hydraulic press machine technology, people are paying more and more attention to its noise.

During the production and use of servo hydraulic presses, in addition to paying attention to operating standards and...

Goodsjack/Delishi Hydraulic Machinery Co., Ltd. is a professional manufacturer of servo hydraulic presses including carbon fiber hydraulic platen press, deep drawing press...

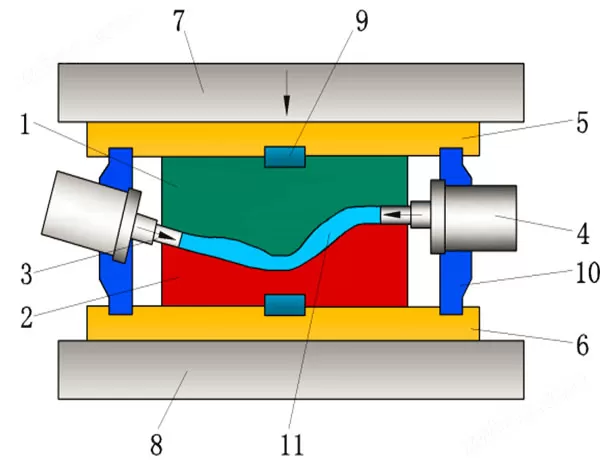

Internal high pressure forming equipment is composed of "clamping press" and "internal high pressure system".

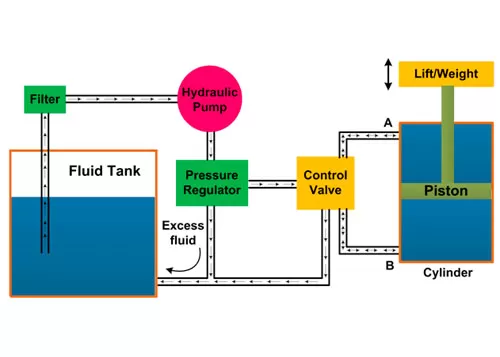

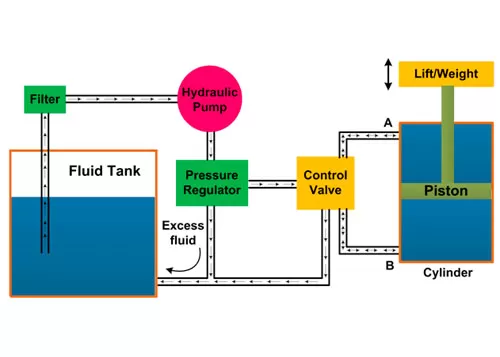

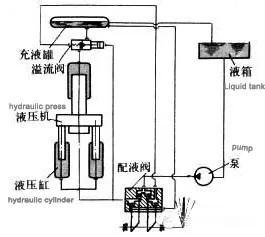

The hydraulic system is the core component of the hydraulic press machine, and its normal operation is crucial to the...

The hydraulic system is the core component of hydraulic press machine. It transmits and control through the pressure of ....

As a mechanical equipment in the manufacturing industry, the normal operation of the hydraulic press determines the production cost and production efficiency, which directly...

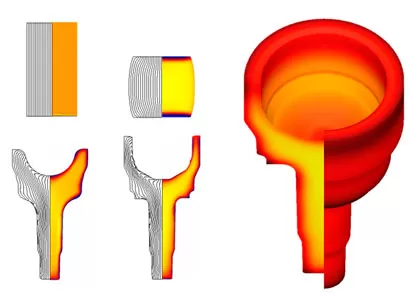

Deep Drawing Press is suitable Deep Drawing Materials Forming. Not only general materials made of metal, copper...

The frequency converter is used to drive the motor to drive the oil pump, and the oil pump provides high-pressure working fluid to the hydraulic cylinder to push the movable beam to move up and down.

Hydraulic Press for Fiber Thermoforming is a hot press that integrates heating, pressure maintaining, pressure replenishment, vacuuming, and vacuum breaking.

A new hot forging press technology is poised to revolutionize the metal forming industry. This innovative technology......