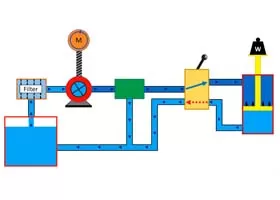

The hydraulic circuit selection for hydraulic press, must start with the selection of the speed regulating circuit (including determining the circulation method of the oil passage and the oil source structure method).

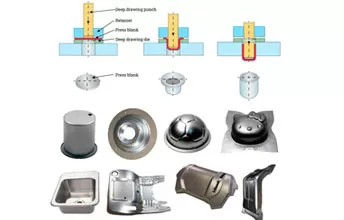

Goodsjack/Delishi Hydraulic Machinery is an industry-leading innovator of servo hydraulic press and fabrications specializing in progressive and deep drawn metal stamping, automated...

Installing a hydraulic press machine requires careful planning and adherence to safety standards. We have professional after-sales service personnel to provide you with hydraulic...

Goodsjack/Delishi Hydraulic Machinery, a company specializing in hydraulic presses for various industries, including the energy sector. Precise Hydraulic Battery presses to make ...

The future development direction of hydraulic press machines: intelligence and automation, improving energy efficiency and reducing noise. In recent years, with the continuous...

Manufacturing a hydraulic press machine requires not only theoretical knowledge, but also rich practical experience. Every aspect from design to production requires careful planning...

Hydraulic press machines have high profits and the ability to generate revenue, which can significantly improve production efficiency and reduce production costs, thereby creating...

After more than 20 years of unremitting efforts, Goodsjack/Delishi Hydraulic Machinery has obtained multiple...

Wearable small parts of hydraulic press machine that are easy to break,rubber accessories,electrical components...

A hydraulic press machine is a mechanical device that uses liquid to transmit force and has a wide range of applications.

Frame hydraulic press machine is an important machine for the production of modern industrial spare parts. It is suitable...

It is not difficult to operate a hydraulic press machine. The rare thing is that you have to operate it safely without damaging the hydraulic press machine, which is not easy. So how should you operate a hydraulic press machine safely.

With the transformation and upgrading of the manufacturing industry and the change of market demand, the functional requirements of hydraulic press machines are getting higher and higher.

We can look at the technical parameters of the hydraulic press machine, and know where the price is. How to identify...

Hydraulic press machine, as a powerful and precise tool, can exert huge pressure, perfectly simulating the real use environment. A hydraulic press machine and a set of wrenches from different countries will compete in a desperate battle in this challenge.