Our Spring Festival is approaching. Please kindly be advised that our Chinese New Year holiday is scheduled as follows:

President Xi Jinping Meets with U.S. President Joe Biden in Bali. The leaders of the two countries jointly advocated the construction of an open world economy. Xi Jinping pointed out that the world is at a major historical turning point, and countries need to face unprecedented challenges and seize unprecedented opportunities.

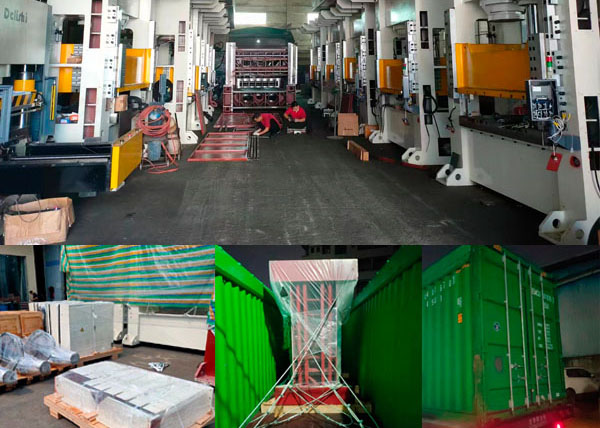

After nearly 2 months hydraulic press machine processing and testing, now we'll pakage the machine and delivery to customer.

Speed-increasing Optimal Design of Hydraulic Press Machine

The hydraulic press machine is studied on the basis of absorbing Western advanced experience and technology. Today, with the increasingly developed technology power, the performance of the hydraulic press machine is gradually increasing.

Thank you customers for their trust in our hydraulic press machines! After more than two months of hard work..

SMC table-tennis table is a typical fitness equipment. At present, the mainstream production method is a one-time molding process of hydraulic press machine.

The Hydraulic Compression Molding Press for Graphite Saggar adopts a four-beam and four-column structure, and the pressing method is that the upper pressing mold frame floats, which produces the required relative motion to the lower mold to achieve the double-sided pressing effect.

Hydraulic press machine for molded aramid ballistic helmet, recommended composite material hydraulic press, mainly used for the forming process of various composite materials, such as glass fiber reinforced plastic resin composite materials, SMC, BMC, Kevlar and other materials

Our automatic ceramic power compacting press machines(also called ceramic power hydraulic presses) are manufactured in capacities from 50 tons to 5000 tons for single-level or multi-level parts for carbides, ceramics, powder metals, polymers and other particulate material industries.

Hydraulic presses play an important role in the automotive manufacturing industry. According to statistics, 60% to 80% of the parts on the car are produced by hydraulic press machine. Therefore, the hydraulic press machine has an important influence on the product quality, production efficiency and production cost of the automobile.

The structure of the car door sheet metal parts is complex, which affects the overall performance of the car door. According to the processing requirements of the car door, the car door sheet metal drawing hydraulic press can be selected. With the mold, the car door sheet metal can be integrally formed. This hydraulic press adopts frame structure, which can significantly improve product quality.

The precision servo CNC hydraulic press drives the oil cylinder to perform the upper and lower pressing operations through the CNC hydraulic system. The man-machine interface operation window is connected, and the pressing parameters of the product can be set according to the customer's pressing product on the configuration touch screen, which can intuitively view the pressing of the product.

According to the structure, hydraulic presses are mainly divided into: four-column hydraulic press (three-beam four-column type, five-beam four-column type), double-column hydraulic press, single-column hydraulic press (C-shaped structure), frame hydraulic press, etc.

How time flies! Our Spring Festival is approaching.