1. Regularly replace the hydraulic oil

Hydraulic oil is the blood of the hydraulic system, and its quality directly affects the working effect of the hydraulic system. Therefore, regular replacement of hydraulic oil is an important step in maintaining the hydraulic system. According to the usage and working environment of the hydraulic press machine, it is generally recommended to replace the hydraulic oil every 6 months to 1 year. When replacing hydraulic oil, care should be taken to select suitable oil products and ensure a clean oil circuit system to prevent impurities from entering the hydraulic system.

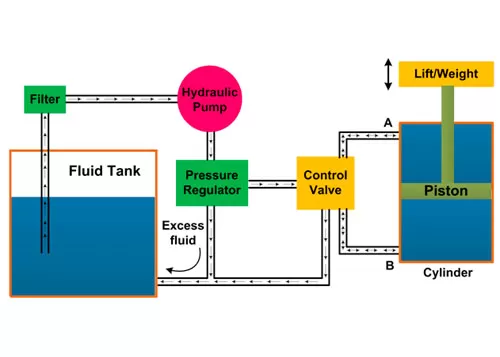

2. Check hydraulic oil filter

The function of the hydraulic oil filter is to filter the impurities and pollutants in the hydraulic oil and keep the hydraulic oil clean. Regularly check the working status of the hydraulic oil filter. If the filter element is found to have expired or there are obvious pollutants on the filter element, the filter element should be replaced in time. At the same time, the shell of the hydraulic oil filter should be cleaned regularly to ensure its normal operation.

3. Check hydraulic lines and connections

Hydraulic lines and fittings are parts of hydraulic systems that are prone to leaks and wear. Regularly check the connection of hydraulic lines and joints to ensure that they are tight and reliable to avoid leakage. At the same time, check the wear of hydraulic pipelines and joints, and replace them in time if they are worn, so as not to affect the normal operation of the hydraulic system.

4. Check hydraulic pumps and valves

Hydraulic pumps and valves are the core components of the hydraulic system, and their working status directly affects the performance of the hydraulic system. Regularly check the working conditions of hydraulic pumps and valves, and repair or replace them in time if any problems such as abnormal sound, temperature rise or unstable operation are found. At the same time, the shells of hydraulic pumps and valves should be cleaned regularly to ensure their normal operation.

5. Check the hydraulic cylinder regularly

The hydraulic cylinder is a common actuator in the hydraulic press machine, and its working state directly affects the working effect of the hydraulic press machine. Regularly check the sealing performance and working status of the hydraulic cylinder. If leakage or unstable work is found, repair or replace it in time. At the same time, the shell of the hydraulic cylinder should be cleaned regularly to ensure its normal operation.

To sum up, the maintenance of the hydraulic system of the hydraulic press machine, is the key to ensuring the normal operation of the hydraulic press machine. By regularly replacing hydraulic oil, checking the working status of hydraulic oil filters, hydraulic lines and joints, hydraulic pumps and valves, hydraulic cylinders and other components, the service life of hydraulic presses can be effectively extended and work efficiency improved. We hope the introduction of this article is helpful to you, and your hydraulic press machine work smoothly.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail