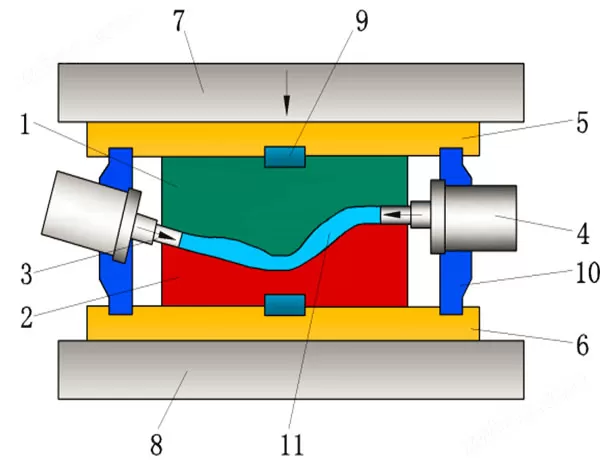

Internal high pressure forming principle and process

Hydroformers presses employ a specialized type of die based process forming known as hydroforming. High pressure fluid is injected into the part causing the metal to expand and take the shape of the die molding. This technique allows for complex shapes to be formed while also producing stronger and lighter components. We have the ability to hydroform most metal materials including, aluminum, brass, carbon steel, copper, precious metals and high strength alloys, as well as stainless steel. Delishi/Goodsjack Hydraulic Machinery manufacturing capacity consists of 1-5000 ton hydraulic presses.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail