1. Preparation before installation

Determine the installation position of the hydraulic system: The hydraulic system should be installed in an environment of good ventilation, dry, and non corrosive gas and chemicals to ensure the normal operation of the system.

Prepare the tools and materials required for installation: including wrenches, screwdrivers, sealing pads, hydraulic oil, etc.

2. The installation step of the hydraulic system

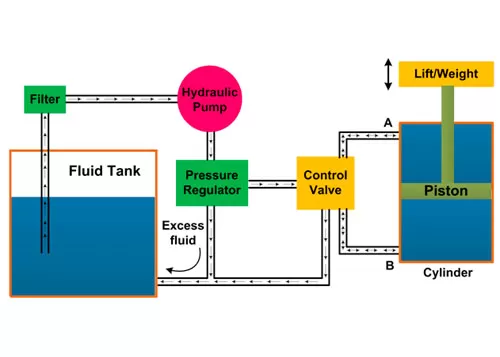

Install the hydraulic pump: Fix the hydraulic pump on the machine to ensure that it is parallel to the motor axis. When installing, pay attention to the import and exit direction of the pump to ensure that the flow of the hydraulic oil is correct.

Install the hydraulic valve group: according to the needs of the hydraulic system, select the appropriate hydraulic valve set, and install it according to the hydraulic drawing. When installing, pay attention to the import and exit direction of the valve group and the sealing of the connection thread.

Install the hydraulic cylinder: According to the needs of the hydraulic system, select the appropriate hydraulic cylinder and install it according to the hydraulic drawing. Pay attention to the import and exit direction of the hydraulic cylinder and the sealing of the thread.

Install hydraulic fuel tank: fix the hydraulic fuel tank on the machine tool, and connect the oil pipes of the hydraulic pump, hydraulic valve set and the hydraulic cylinder. When installing, pay attention to the length and curvature of the oil pipe to ensure that the flow of the liquid oil is unblocked.

Install the hydraulic oil filter: Inlet the hydraulic oil filter is installed at the oil inlet of the hydraulic fuel tank to filter the impurities and pollutants in the oil to protect the normal operation of the hydraulic system.

3. Debugging after installation

Check whether the connection of the hydraulic system is firm: Check whether the connection thread of the hydraulic pump, hydraulic valve group, hydraulic cylinder and hydraulic fuel tank is tightened to ensure the sealing of the system.

Check whether the flow of the hydraulic oil is correct: Open the oil pump of the hydraulic system to observe whether the flow of the hydraulic oil is consistent with the hydraulic drawing. If there is any error, adjust it in time.

Check whether the pressure of the hydraulic system is normal: To detect whether the pressure of the hydraulic system is within the design range through the pressure gauge, it should be adjusted in time if there are abnormalities.

Check whether the action of the hydraulic system is flexible: By operating the hydraulic valve group and the hydraulic cylinder, observe whether the movement of the hydraulic system is flexible.

Through the above installation steps and debugging, we can ensure the normal operation of the hydraulic system of the oil compressor. During the installation process, you need to pay attention to the following points:

1. Before installing, carefully read the installation instructions and hydraulic drawings of the hydraulic system to ensure that the installation is correct.

2. Pay attention to the sealing of the hydraulic system during installation to avoid hydraulic oil leakage.

3. Check the oil quality and oil level of the hydraulic system regularly, and replace and supplement hydraulic oil in time.

4. Regularly check the various components of the hydraulic system, such as hydraulic pumps, hydraulic valve sets, and hydraulic cylinders to replace damaged components in time.

In short, the proper installation of the hydraulic system is the key to ensuring the normal operation of the oil compressor. I hope the above introduction will be helpful to everyone.

Goodsjack/Deishi has more than ten years of experience in R&D, design and production of equipment manufacturing equipment in the fuel cell industry. It has been designing and producing various special equipment for large enterprises and serving many enterprises. If you need hydraulic press machine, please contact us, best hydraulic press solution will be provided for you.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail