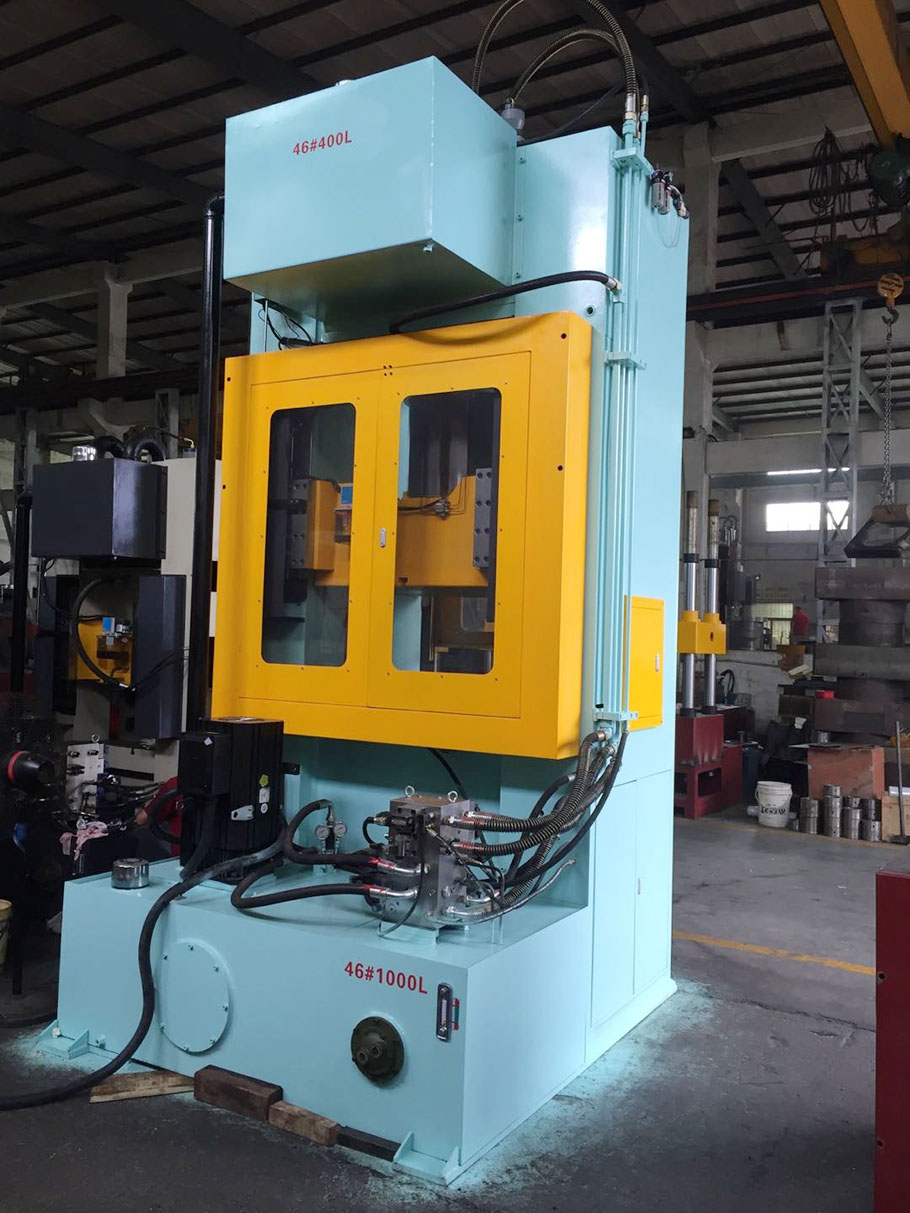

Picture Show

Product Application

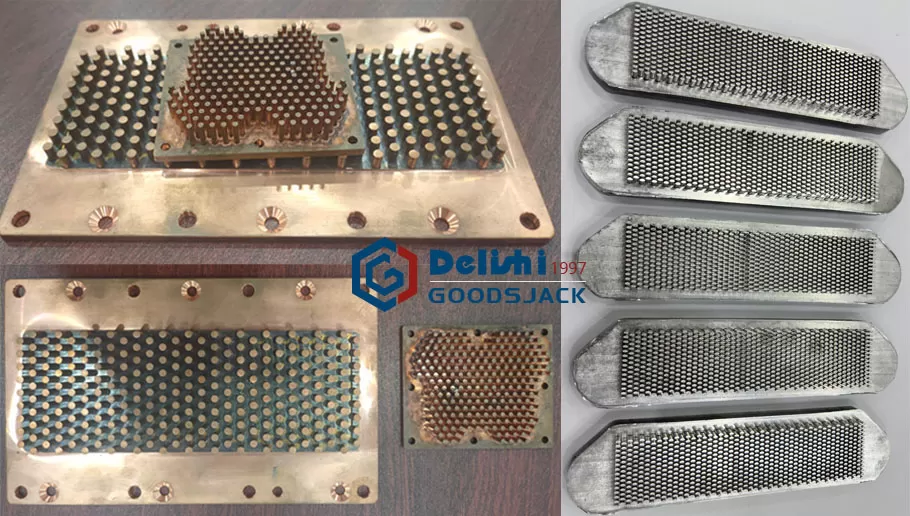

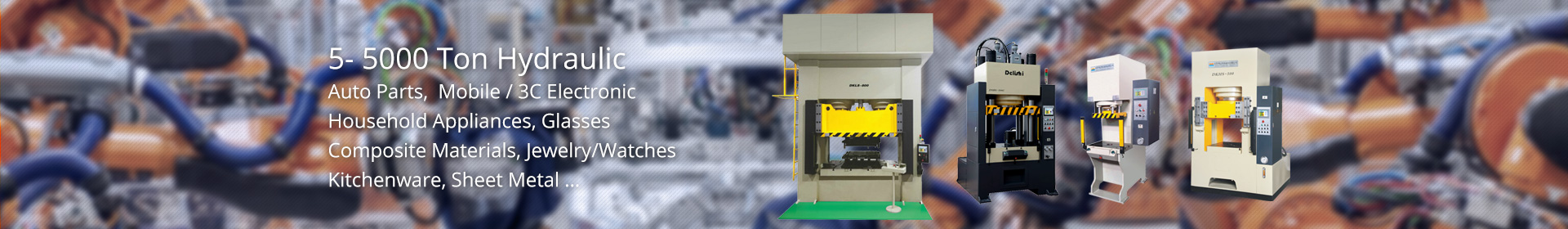

1. This cold forging press was mainly applicable to metal materials of cold extrusion, forming, shallow, drawing and blanking purposes Such as: automobile gears, car universal joints, motorcycle spare parts, cell phone casing, LED radiator, aluminum heat sink, watchband, watchcase and hardware tools etc.

2. Stamping, forming, shallow, drawing and pressing assembly etc. Especially suitable for the precision molding parts.

Goodsjack 800 tons cold forging press is pressing car universal joints

Goodsjack 650 tons cold forging press is pressing LED heat sink

Video

Technical Parameters

| Model | Units | Specifications | ||||||||||

| DKHS-100 | DKHS-200 | DKHS-300 | DKHS-400 | DKHS-500 | DKHS-650 | DKHS-800 | DKHS-1000 | DKHS-1200 | DKHS-1500 | |||

| master cylinder | rated capacity |

ton | 100 | 200 | 300 | 400 | 500 | 650 | 800 | 1000 | 1200 | 1500 |

| stroke | mm | 300 | 400 | 400 | 400 | 500 | 500 | 500 | 500 | 500 | 400 | |

| fast dowm speed |

mm/s | 180 | 160 | 160 | 230 | 230 | 170 | 190 | 210 | 190 | 220 | |

| coining speed |

mm/s | 7-15 | 8-17 | 5-12 | 7-18 | 8-16 | 5-12 | 5-12 | 8-16 | 6-15 | 3-13 | |

| return speed |

mm/s | 170 | 150 | 130 | 210 | 200 | 170 | 180 | 210 | 160 | 210 | |

| system pressure | bar | 240 | 235 | 240 | 240 | 250 | 248 | 240 | 240 | 250 | 240 | |

| knock-out cyinder | ejecting force |

ton | 15 | 30 | 30 | 40 | 40 | 50 | 50 | 60 | 80 | 100 |

| stroke | mm | 200 | 200 | 200 | 200 | 250 | 250 | 250 | 250 | 250 | 200 | |

| mandrel diameter |

mm | 40 | 50 | 50 | 60 | 60 | 80 | 80 | 80 | 80 | 100 | |

| open heigh(slide to bolster) | mm | 600 | 700 | 700 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1050 | |

| working table size |

L-R | mm | 500 | 700 | 700 | 800 | 800 | 1000 | 1000 | 1200 | 1300 | 1400 |

| F-B | mm | 500 | 700 | 700 | 800 | 800 | 1000 | 1100 | 1200 | 1300 | 1400 | |

| main motor power | KW | 8.6 | 16 | 23.6 | 34.6 | 34.6 | 37 | 60 | 74 | 90 | 110 | |

| over all dimension |

L-R | mm | 1250 | 1680 | 1680 | 2600 | 2650 | 2940 | 3000 | 3660 | 3800 | 4150 |

| F-B | mm | 1430 | 1780 | 1780 | 2100 | 2100 | 2100 | 2300 | 2450 | 2500 | 2680 | |

| H | mm | 2850 | 3480 | 3500 | 3700 | 4050 | 4100 | 4320 | 4560 | 4720 | 4820 | |

Remarks: Above 1500 ton frmae guide cold extrusion press machine, please tell us your requirements, such as product drawing etc, then best offer wil be sent to you!

Product Advantage

Goodsjack DLS cold forging press was mainly applicable to metal materials of cold extrusion, forming, shallow, drawing and blanking purposes Such as: automobile gears, car universal joints, motorcycle spare parts, cell phone casing, LED radiator, aluminum heat sink, watchband, watchcase, hardware tools etc.

Use servo control system to save energy 50-70%.

Pressure stability,pressure error ±1bar,repeatable positioning accuracy up to±0.02mm.

Modular design, customized to your cutting specifications

Perfect stability and effective resistance to off-center loading

Superior rigidity and bed to platen parallelism for perfect stamping result

Precision-guided moving slide (platen)

Particularly suitable for precision stamping automotive parts

Fast, easy and safe setup and operation

Years of maintenance-free and reliable operation

Manufacture Ability

Certifications

Service Cases

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail