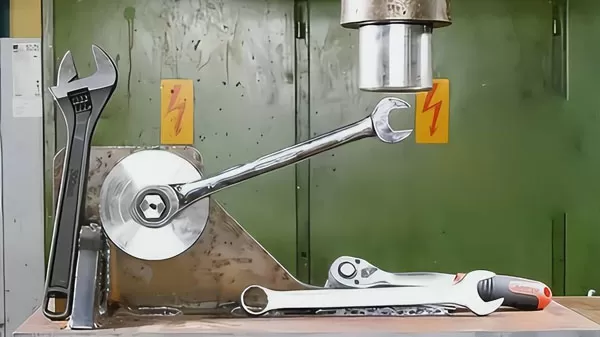

What are the results of using hydraulic press to press wrenches from different countries? Which wrench is more resistant to pressure?

We need to understand the wrench manufacturing technology and material quality of each country. At present, some developed countries in the world, such as Germany, Japan and the United States, have high technical strength and strict quality control in tool manufacturing. They are able to use high-quality alloy steel materials to manufacture wrenches and use advanced heat treatment processes to improve the hardness and wear resistance of the wrenches. In contrast, some developing countries may be relatively backward in wrench manufacturing, and their technology and material quality may not be comparable to developed countries.

We need to consider the design structure of the wrench. There are many different types of wrenches on the market today, such as adjustable wrenches, fixed wrenches, pipe wrenches, etc. The design of each wrench affects its ability to withstand pressure. Properly designed, compact wrenches will generally be able to withstand higher pressures, while poorly designed or loosely constructed wrenches may be prone to deformation or damage under high pressures.

We need to take into account the amount of pressure exerted by the hydraulic press. The pressure of a hydraulic press may vary, depending on the specific application and needs. Greater pressure usually means greater demands on the wrench, since greater pressure puts a greater load on the wrench. Therefore, wrenches that can withstand higher pressures tend to be more pressure resistant.

Hydraulic press experiments mean the importance of quality control for the wrench industry. In the hydraulic press experiment, there are strict requirements for the performance parameters of each component of the system and hydraulic components, in order to ensure the normal operation of the hydraulic system. Similarly, the wrench industry also needs to focus on product quality control.

Only by taking quality control as an important link can we produce high-quality products and ensure product reliability and service life. The significance of the hydraulic press experiment for quality control is to remind the wrench industry that every aspect of the product should be paid attention to, from the selection of raw materials to the control of the manufacturing process, all must be carefully controlled to ensure stable product quality.

The hydraulic press experiment also provides reference for innovative design and user experience in the wrench industry. In the hydraulic press experiment, the design of the hydraulic system must meet the requirements of compact structure, small size, and good performance. This is also a good reference for the design of the wrench industry. The wrench industry can apply hydraulic technology to the structure of the wrench through innovative design, reduce the size of the wrench, and improve the performance of the wrench. In addition, the hydraulic press experiment also reminds the wrench industry to pay attention to user experience and focus on the humanized design and ease of use of products to provide a better user experience and meet user needs.

In the end, no matter which country's wrenches are better, this experiment shows us the diversity of wrench quality and technology, and also allows us to think more deeply about consumer needs and diversity of choices. Let's find the right choice for you in the world of wrenches.

+86-769-8306-1993

+86-769-8306-1993

E-mail

E-mail